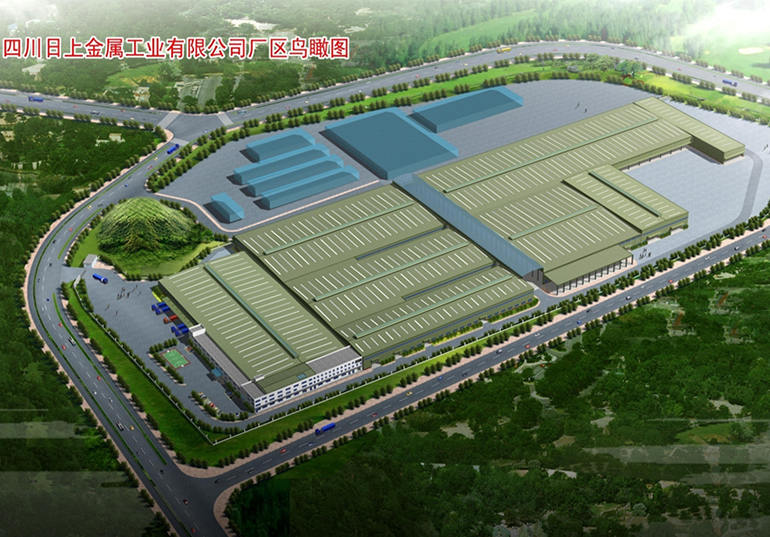

Located in Jimei District, Xiamen, Xiamen Sunrise Group Co., Ltd is the first production base built by Xiamen Sunrise Group in 2002, specializing in the production of steel wheels for trucks and buses, cars and trailers, with a total project area of 33,000 square meters and a total investment of 150 million RMB. The project was completed and started production in 2002. After the production of Xiamen Sunrise Group's headquarter factory, the annual production scale of steel wheels has reached to an annual output of 2 million pcs, and the annual sales volume has reached 380 million RMB. The products are mainly covered in the export markets of Europe and America, CIS, Asia and Australia, Central and South America, Middle East and Africa as well as the domestic supporting markets and the aftermarkets of East China, Central China and South China.

Technological Process

Rim Technological Process Route

Disc Technological Process Route

Assemble Technological Process Route

Painting Technological Process Route

Material Technological Process Route

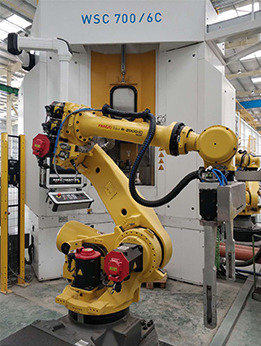

Forging and Spinning

Heating Treatment

Machining

Cleaning and Packing

R&D Technology

-

Testing Equipment for Material Properties

Testing Equipment for Material Properties -

Wheel Radial Fatigue Testing Machine

Wheel Radial Fatigue Testing Machine -

Wheel Cornering Fatigue Testing Machine

Wheel Cornering Fatigue Testing Machine -

Salt Spray Testing Machine

Salt Spray Testing Machine

Quality System

Innovation and Development

The lightweight of vehicles is the development trend of vehicle manufacturing industry; automobile wheel is the key component of vehicle running. Our company had co-researched and made solid cooperative relations with Shougang Group. The current 22.5x8.25 specification 15°DC steel wheel made of 6mm-380CL wheel steel have been in batch use in the US market for more than 10 years, and never occurred any quality problems.

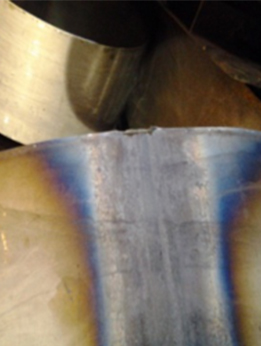

General rim with 6mm-380CL, using the existing continuous flash butt-welding equipment can ensure the welding quality and pass rate. Light weight rim are made of 5mm-590CL materials, as with existing continuous flash butt welding equipment, heat affected zone flaring, dilatation and thinning cracking are very easy to occur. After technology upgrades of research and development, and by using pulse flash butt welding machine, our company’s lightweight wheel cracking rate was reduced from 10%-23% to 1.0%.

- About Us

- Company Profile

- Our History

- Company Culture

- Operation Philosophy

- Social Responsibility

- System Authentication

- Staff Presence

- Products Center

- OTR/Industrial Wheel

- Agricultural Wheel

- Tubetype Light Truck Steel Wheel

- Tubetype Truck and Bus Steel Wheel

- Tubeless Demountable Steel Wheel

- Tubeless Light Truck Steel Wheel

- Tubeless Truck and Bus Steel Wheel

- Tubeless Truck and Bus Forged Aluminum Wheel

- Passenger Forged Aluminum Wheel

- ST Trailer Wheel

- Production And R&D

- Production Base

- Technological Process

- R&D Technology

- Quality System

- Innovation and Development

版权所有 © 2012 厦门日上集团股份有限公司 闽ICP备05017532号-1